In recent years, laser machines have become increasingly prevalent in technology and industry. From industrial manufacturing to medical treatments, these powerful devices have revolutionized the way we approach complex tasks.

But just what is the science behind them? In this article, we take a deep dive into the mechanics of laser machines to explore how they work, their advantages over traditional technologies, and potential applications for this exciting new technology.

Anatomy of a Laser Machine

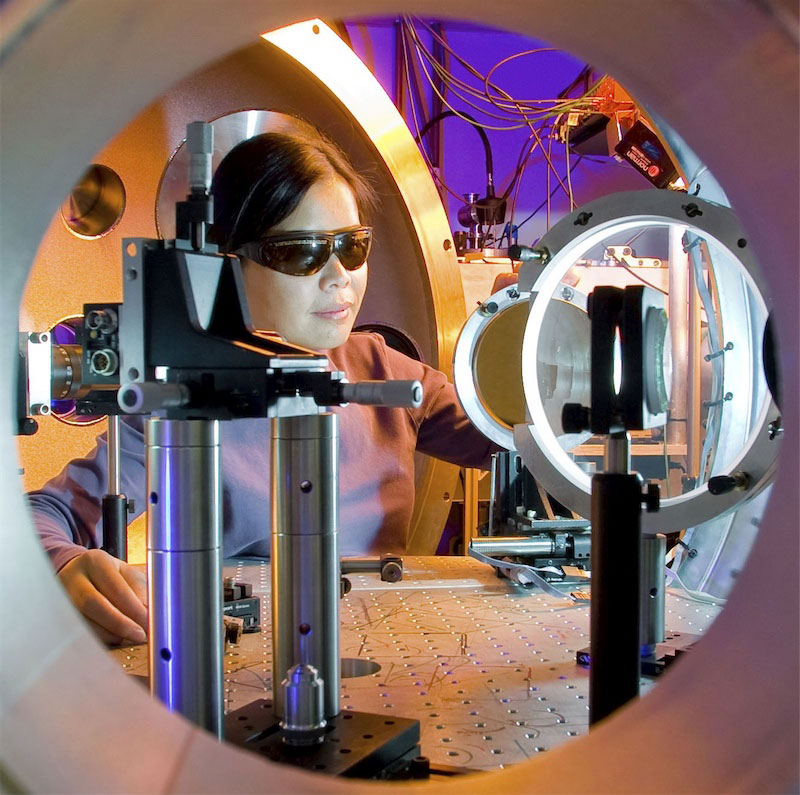

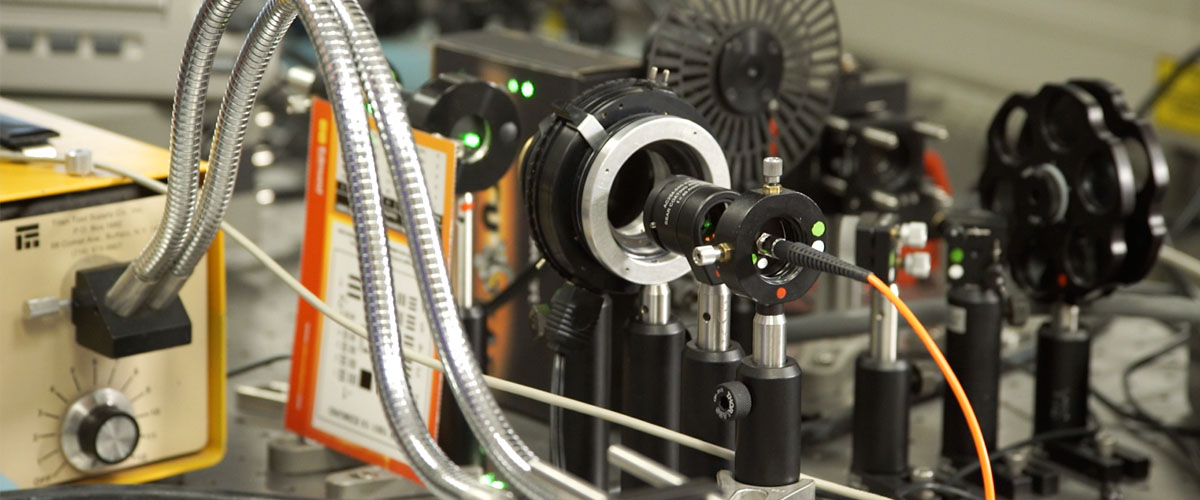

The anatomy of a laser machine is complex and fascinating. It consists of several components, each designed to contribute to the overall effectiveness of the machine.

At its core lies an optical cavity containing two mirrors that reflect light back and forth through a lasing medium, such as a crystal or gas, generating intense beams of light. This light passes through an aperture in one mirror before being focused by lenses onto the target material.

The intensity of this beam is controlled by varying variables such as pulse duration and power output which can be adjusted depending on the application. Additionally, there are often additional elements included within the laser system to ensure accuracy like Galvo scanners for faster scanning rates and positioners for precise movement control. All these parts combine to create highly versatile machines capable of cutting materials with extreme precision while maintaining high safety standards due to their non-contact nature.

The Physics Behind Lasers

When it comes to the physics behind laser machines, there is a wealth of knowledge that must be understood to appreciate their capabilities. Lasers are devices that generate light and emit an intense beam of radiation, usually in the form of infrared or visible light.

This energy has been harnessed through the use of different types of crystals, lenses, and other components that can control its direction and intensity. By understanding how these components interact with one another, scientists have been able to create powerful lasers capable of cutting through metal or performing delicate surgeries.

At its core, the science behind laser machines depends on two fundamental concepts: refraction and reflection. Refraction occurs when light passes through a medium such as glass or water at an angle; this causes the light rays to bend away from their original path.

On the other hand, reflection is what happens when a beam bounces off a surface like a mirror; this allows for greater accuracy in directing beams into desired locations without wasting energy by having them scatter everywhere else instead. With these laws governing how laser beams are directed and controlled, engineers can manipulate them into higher-power tools such as those used for industrial cutting purposes or medical treatments like eye surgery. The combination of refraction and reflection also makes it possible for lasers to be highly precise instruments because they can remain focused over long distances without losing strength – even if they are pointed towards objects far away from where they were created! This level of precision is further enhanced by using special mirrors that act as filters between two points so that only certain wavelengths can pass through while others get blocked out completely; this helps ensure that whatever task is being undertaken will not be impeded by any unexpected environmental factors such as air turbulence or dust particles blocking parts of the beam’s pathway along its journey from source point A all way until destination B!

Safety Considerations for Working with Laser Machines

When it comes to safety considerations for working with laser machines, the risks posed by these powerful tools should not be underestimated. Laser machines have the potential to cause serious harm to people and property if they are misused or handled carelessly.

Anyone operating a laser machine must take the necessary precautions to ensure their safety as well as those around them. The most common safety measures include wearing protective eyewear, using appropriate ventilation systems, and avoiding skin exposure during the operation of the equipment.

Additionally, operators must make sure that all electrical components and connections are securely mounted and properly insulated from possible sparks or overheating elements. Furthermore, all personnel present in an area where a laser machine is being operated should keep clear of any reflective surfaces which may be within range of the beam’s path as this could result in serious injury due to direct contact with highly concentrated light radiation.

Finally, when storing or transporting a laser machine one must use sturdy cases designed specifically for that purpose since mishandling can lead to accidental activation and subsequent hazards such as fire or electric shock caused by improper wiring or damaged insulation materials used during construction of the device itself.

Conclusion

Laser Machines are a marvel of modern engineering. With their precision and accuracy, they have revolutionized the way we work and live.

The science behind Laser Machines is a fascinating example of how far technological advancements can take us. By combining high-powered laser light with complex control systems, these machines offer unmatched capabilities in terms of speed and accuracy.

As such, Laser Machines have become an essential tool for many businesses across various industries, making them invaluable assets to any organization looking to maximize efficiency and productivity.